-

-

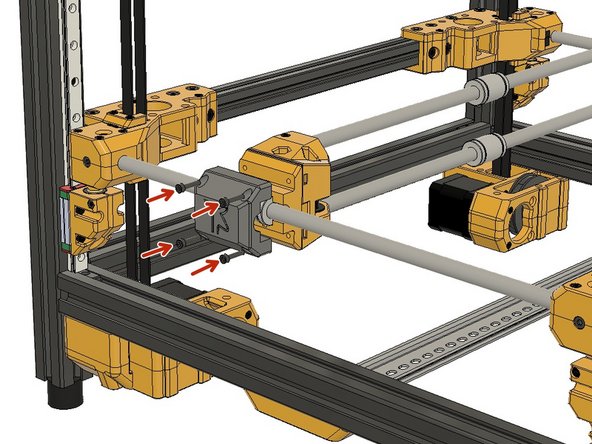

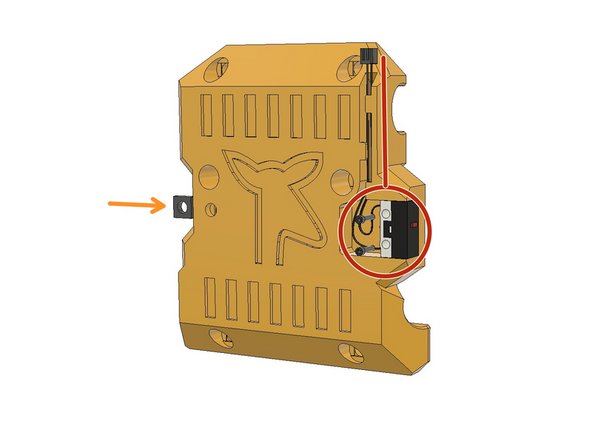

Find the part labelled as XR (X-Axis Right) and insert the M3 Square Nuts all the way in. Our tolerances are tight; please use a plier to insert the square nut if necessary.

-

Screw the M3 x 10mm Screws but do not tighten them yet. You will do it later to lock the X-Axis Steel Rods.

-

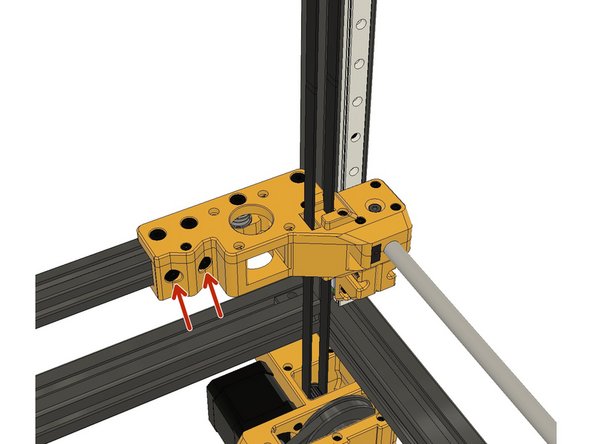

Push the M5 Hex Nuts all the way into the hex slots at the bottom of the XR part. Top slots for M5 screws are hex-shaped on purpose but they are larger and you can't keep the hex nuts in place in them so you won't be able to do a mistake.

-

-

-

Combine the two F695ZZ bearings and insert them into the slot. Screw an M5 x 30 Ultra Low Head screw to fix the idler assembly.

-

Push the GT2 20T Idler Pulley into the slot and screw the M5 x 30 Ultra-Low Head Screw

-

Follow the same steps for the part labelled XL (X-Axis Left).

-

-

-

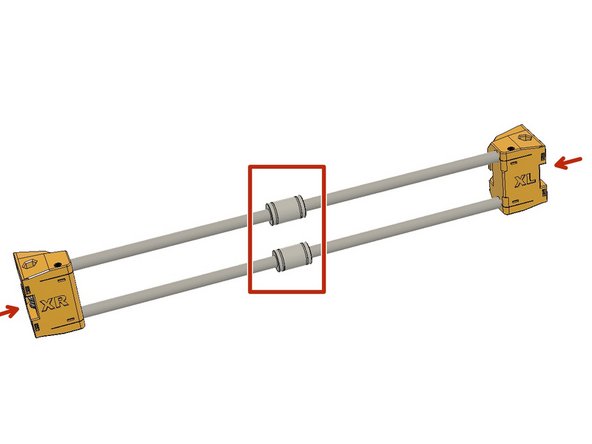

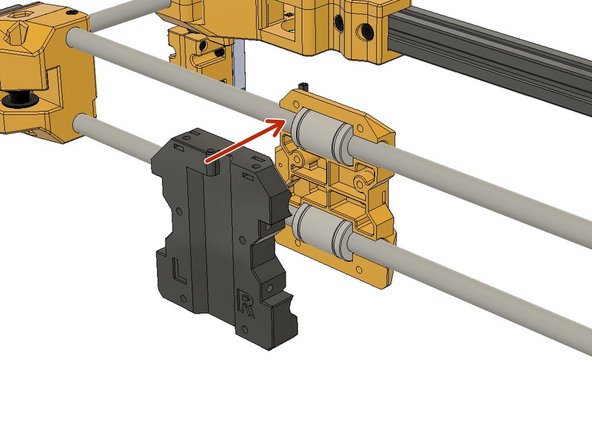

Slide in the LMU10 Bearings on the X-Axis Rods and wipe off the excess lube on the ends. Insert the XR and XL parts to the rod end. Do not tighten the Rod screws yet.

-

Find the part labelled XC (X-Axis Carriage) and insert the LMU10 on the Y-Axis rod.

-

-

-

Tighten the zip ties.

-

Place the bearing cover and insert four M3 x 14 screws to prepare for the right side mount of the X-Axis.

-

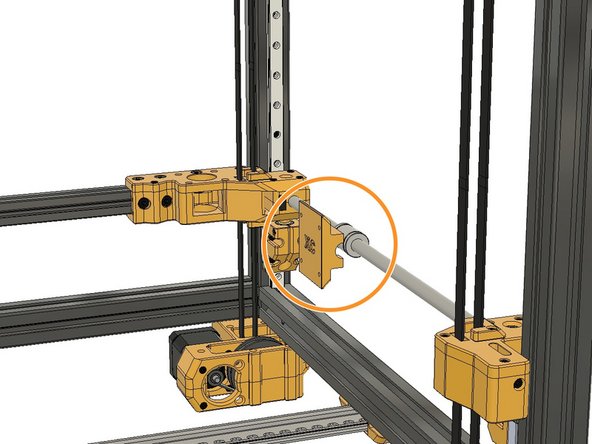

Mount the XR (X-Axis Right) on the XC and tighten the screws.

-

-

-

Please follow the same steps for the XL and XC assembly on the left. Tighten the Zip Ties and place the bearing cover and mount it with M3 x 14mm screws.

-

-

-

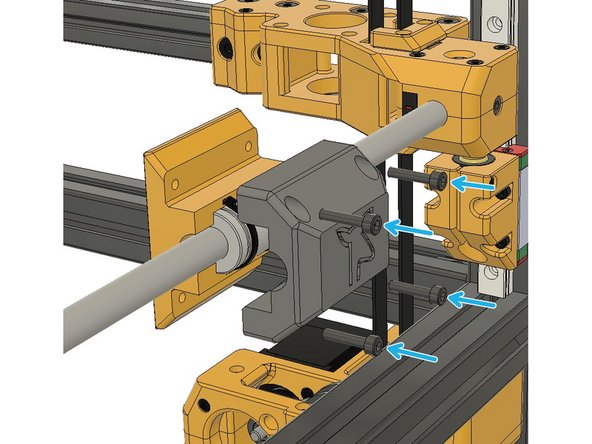

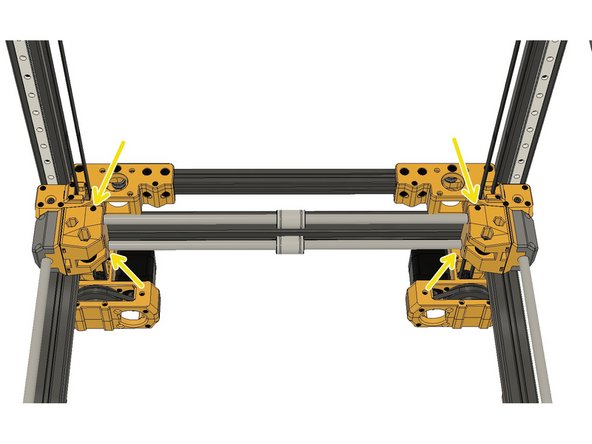

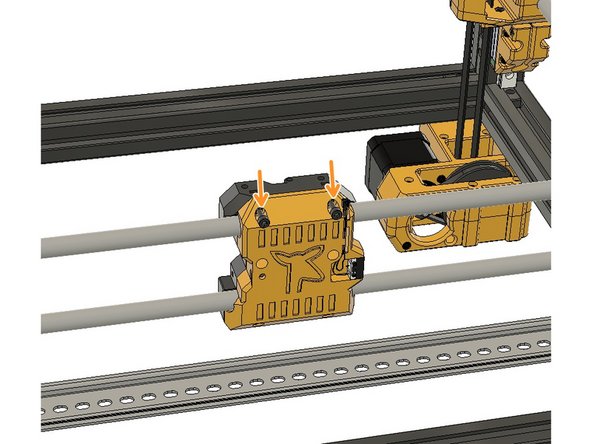

If you remember, we only tighten these two M5 x 10mm screws temporarily on the A Carriage on previous steps while assembling the gantry. Now, please loosen these two screws slightly.

-

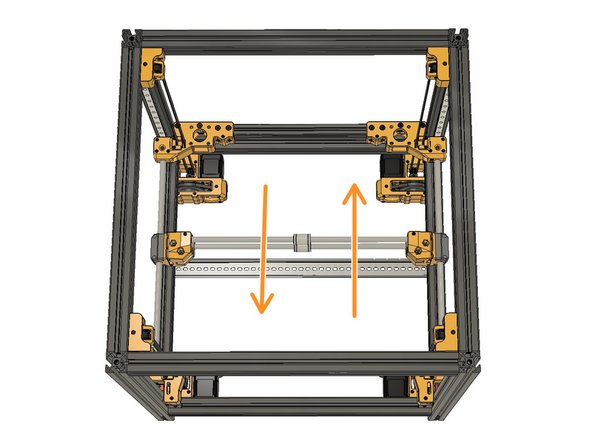

Move the X-Axis back and forth to ensure that it is moving smoothly.

-

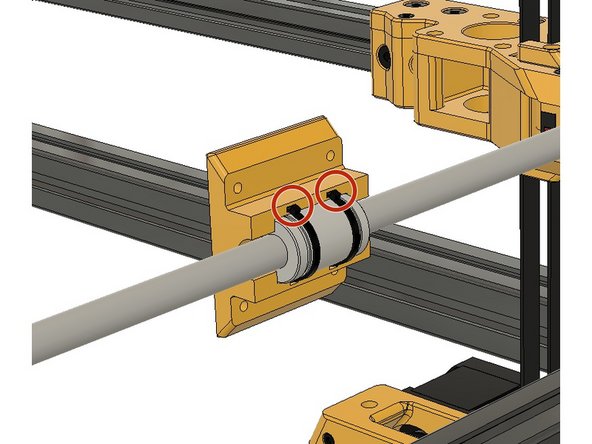

Now move the X-Axis all the way back and tighten the four set screws for the rods on the XR and XL parts.

-

-

-

Move the X-Axis back and forth and ensure free movement. Then tighten the six M5 x 10mm screws on the A Carriage.

-

Drop-in T-nuts are very useful, however, they need to be used properly. If you do not leave enough space to let them move, they won't function as you expected.

-

-

-

Pass the endstop cables as seen in the picture and mount the endstop with two M2 x 10mm screws.

-

Insert an M3 Square Nut on the left side for radial fan support. Again, our tolerances are tight; please use a plier to insert the square nut if necessary.

-

Find the X Carriage Body Part labelled as L and R. Insert four square nuts to their places on top and front.

-

Turn the backside of the carriage body and insert four M3 Square Nuts all the way in.

-

-

-

Place the bearing cover first and piece together the X Carriage labelled as L and R.

-

Use two M3 x 8mm and unite the bearing cover and X-Carriage. It is normal to be loose at the bottom, you will be tightening all assembly with the Extruder Body.

-

Cancel: I did not complete this guide.

2 other people completed this guide.